We welcome questions and comments about our products and services, you can reach us as follows:

We welcome questions and comments about our products and services, you can reach us as follows:

Versaperm Limited

10 Rawcliffe House

Howarth Road

Maidenhead

Berkshire

SL6 1AP

UK

Tel UK: +44 (0) 1628 777668

Tel USA: +1 (617) 855-7477

e.mail: webcontact@versaperm.com

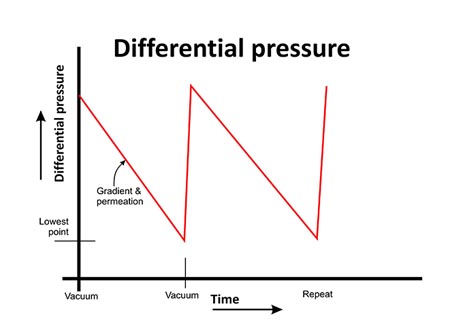

This instrumental technique for measuring vapour permeability is based around a chamber which is split into two halves with the sample under test clamped firmly between the two and acting as a barrier. The gas or vapour is supplied to the sample at a relatively higher pressure on one side than the other. This is usually achieved by evacuating both sides of the chamber, isolating the chamber from the vacuum, and then providing the vapour under test to one side. As the vapour passes through the sample, the pressure on the vacuum side increases, and the gradient of the pressure increase is proportional to the permeation rate.

This instrumental technique for measuring vapour permeability is based around a chamber which is split into two halves with the sample under test clamped firmly between the two and acting as a barrier. The gas or vapour is supplied to the sample at a relatively higher pressure on one side than the other. This is usually achieved by evacuating both sides of the chamber, isolating the chamber from the vacuum, and then providing the vapour under test to one side. As the vapour passes through the sample, the pressure on the vacuum side increases, and the gradient of the pressure increase is proportional to the permeation rate.

The vacuum side is repeatedly evacuated and isolated and the calculated permeation rate reaches a stable value.

In some cases you may want to test the sample in, for example, a kiln, freezer or pressure chamber. In this case a remote chamber in an open frame can be used with any gases piped between the chamber and the main instrument.

The main advantage of this method is that it can measure most gases, especially if a gas-specific sensor is either unavailable or expensive.

The difficulty with this method is achieving a leak-free seal and the risk of damaging the sample. The difference between the vacuum and atmospheric pressures is particularly problematic.

Versaperm Limited © 2014

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668

e.mail: webcontact@versaperm.com Our Cookies Policy